OUR FLEXIBLE PACKAGING PORTFOLIO

Set yourself aside from competitors by using packaging that’s tailored to your aims, values, and customers. Our products are made using state-of-the-art technology and innovative manufacturing methods; our custom bags, pouches, and films add value for your brand and differentiate your products to make them stand out on the shelf.

We work with companies and partners in a range of industries across the world, including:

Custom Flexible Packaging: Your Complete Guide to Smarter, Sustainable Solutions

In today's market, packaging can't just be an afterthought. It's the first thing a customer sees and handles. It has to protect the product, sure, but it also has to work hard for your brand. Custom flexible packaging tackles this job head-on. At MTPak, we build tough, performance-driven flexible packaging. Our solutions handle real jobs—shipping across continents, standing up to moisture, keeping coffee fresh or pet food protected. We use materials that work harder and last longer, often with recycled or compostable options.

This article breaks down what custom flexible packaging is, its key types, the concrete benefits it offers, and how to choose the right option for your product.

What Is Custom Flexible Packaging?

Think of flexible packaging as any package made from pliable materials like film, foil, or paper laminates. It conforms to the product's shape. You see it everywhere: the stand-up pouch for your coffee, the vacuum-sealed bag for pet food, the foil wrapper for an energy bar. The upside is its lightweight yet strong nature, offering excellent barriers against moisture and oxygen. However, it might not be rigid enough for some very heavy or fragile products without specific reinforcement.

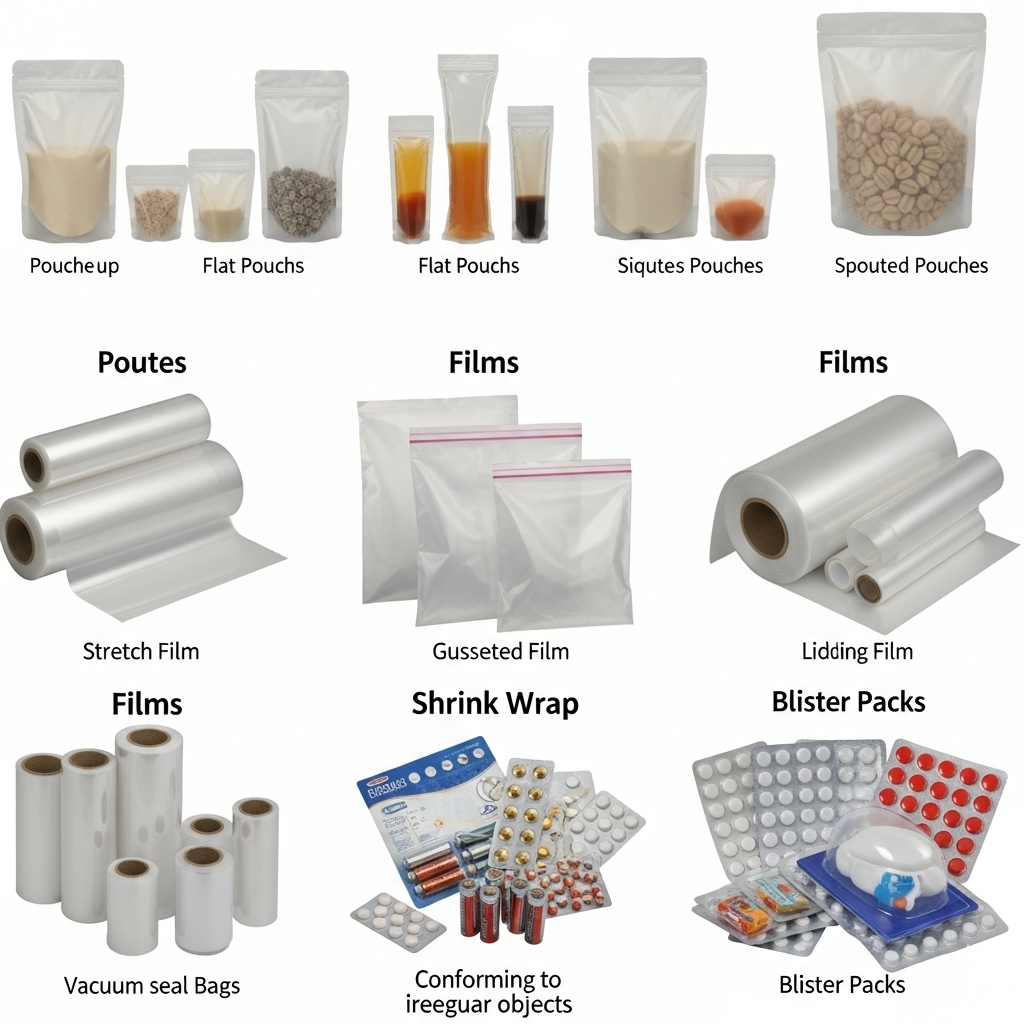

What Types of Flexible Packaging Are Available?

You have multiple options available. Picking the right one comes down to what you need to pack. Think about your product first: coffee beans, pet food, medical devices — all demand a specific kind of protection and functionality.

1. Pouches

For food and drinks, stand-up pouches are the best. They stand up straight on shelves and typically include zippers that can be closed again. For many dry items, flat pouches offer a simpler and cheaper choice.

2. Bags

This includes everything from plain flat bags to gusseted bags (with sides that can be expanded to hold bigger things like pet food or rice) and vacuum bags that suck out air to keep things fresh.

3. Shrink Wrap & Films

Shrink wrap uses heat to safely hold together several items. High-barrier films, which are generally made up of several layers, keep light and air away from delicate things like medicines.

4. Blister Packs

These are common for pills or small electronics and are made up of a pre-formed plastic cavity that is sealed to a backing card. They protect and show off products very well.

What Are the Real Benefits of Custom Flexible Packaging?

Ignore the fancy sales pitches. Let's talk about what this packaging actually does for your operation on the ground. It solves real problems:

Enhanced Brand Identity

It’s your mobile billboard. You print your logo, colors, and designs directly onto the material. This creates instant recognition on a crowded shelf. MTPak uses high-definition printing to make your branding pop.

Superior Product Protection

This is the main job. The right materials act as a barrier. This means longer shelf life for food, protection for sensitive electronics from static, and maintaining sterility for medical devices. The upside is less waste and happier customers. The downside is that you must choose the correct barrier properties—get it wrong, and the product suffers.

Cost and Space Efficiency

Flexible packaging is lightweight, which allows you to cut transportation expenses by a lot, compared to rigid containers. It also takes up less room in warehouses and on trucks so you can ship and keep more goods in each load.

Consumer Experience

Features like easy-open tabs, resealable zippers, or tear notches make a customer's life easier. It’s a simple thing, but it builds loyalty. Adding a QR code is a smart move for engagement.

Environmental Considerations

Let's be practical: flexible packaging often uses less material than rigid alternatives. That is a huge benefit. MTPak offers options like recyclable films, compostable PLA liners, and paper from certified forests (FSC/PEFC). The upside is a smaller environmental footprint, which matters to more shoppers now. The downside is that the recycling infrastructure for some multi-layer films is still playing catch-up.

How Do I Choose the Right Flexible Packaging?

Think like an engineer. It’s about matching the package to the product's needs.

Product Specifications

What’s inside? Consider its weight, shape, and sensitivity to elements like oxygen or moisture. Oils, powders, and liquids all have different requirements. This determines your needed barrier levels (often measured by OTR/WVTR) and material structure.

Regulations and Compliance

This is critical. Food, pet food, and medical products have strict rules. Materials must meet FDA (21 CFR) or EU (EC 1935/2004) standards for food contact. Your supplier must understand this. MTPak’s team gets this right.

Cost Considerations

Customization has a cost. You balance the material expense, printing complexity, and special features (like zippers) against your budget and the value it brings. The upside is a perfect package; the downside is a higher per-unit cost than off-the-shelf options.

Supplier Capability

You need a supplier who can execute. Can they handle the material science? Do they offer the right sustainable options? Can they scale from a small prototype run to full production? MTPak’s facilities, with digital presses and laminators, are built for this exact range of projects.

Which Industries Use Flexible Packaging?

Flexible packaging works best when products need to be protected and easy to use. Different fields typically employ it for certain tasks.

Food & Beverage

Use pouches or vacuum bags for snacks, meats, and drinks. The good thing is that they last longer and are easy to reseal. But materials with high barriers will probably cost more.

Pet Food

Bags for kibble or treats block oxygen and light. This stops grease from going bad. Lightweight design cuts shipping costs. It’s a simple fix for keeping food fresh.

Pharmaceuticals and Nutraceuticals

Foil sachets and blister packs keep medications and powders safe. They follow tight guidelines set by the FDA. Here, accuracy and barrier integrity are very important.

Home and Personal Care

Put shampoo, detergent, and wipes in strong pouches. They don't leak and can be put on shelves. The quality of the print is important for brand attractiveness.

Electronics

Anti-static bags keep circuits safe from moisture and static. The correct film keeps things safe while they are being sent. It's important for delicate parts.

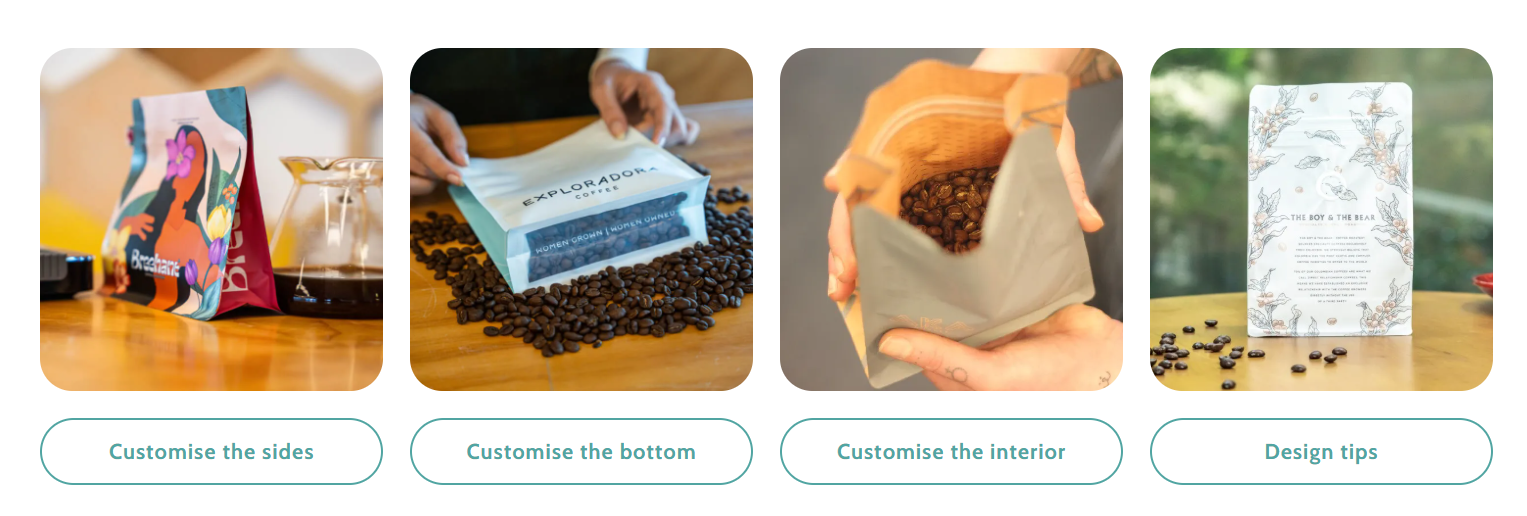

What Customization Options Does MTPak Offer For Flexible Packaging?

At MTPak, we build flexible packaging that works. We produce stand-up pouches for coffee, spout pouches for motor oil, medical bags for sterile devices. Select your material based on need: foil for barrier, kraft paper for natural appearance, and also add features like zippers or valves. Our printing shows your brand clearly, which works well for companies that need specific performance from their packaging.

Conclusion

Custom flexible packaging is a strategic tool. It solves practical problems: protection, cost, shelf impact, and increasingly, sustainability.

At MTPak, we approach packaging like engineers. We provide the expertise to navigate material choices like EVOH barriers, ensure food-grade compliance, and deliver robust construction that runs smoothly on filling lines. Our value is in a no-nonsense partnership, from design to delivery, backed by a global supply chain.

Reach out to our team to get a quote and see how it works.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

Frequently Asked Questions (FAQ)

1. What are some common materials used in flexible packaging?

The common materials are polyethylene (PE), polypropylene (PP), polyester (PET), aluminum foil, and paper. To get the right barrier qualities, they are commonly laminated or co-extruded.

2. Can I check and see if a flexible package is really eco-friendly?

Look for third-party certificates like recyclability labels, compostability certifications (like ASTM D6400), or material sourcing stamps (like FSC/PEFC). Always ask your provider for test results or technical datasheets.

3. Is it possible for MTPak to make packaging with unique seals or closures?

Yes. For increased safety and convenience, we provide alternatives like zippers, spouts, tear notches, and features that show if someone has tampered with them.